Cream Separators

Menu

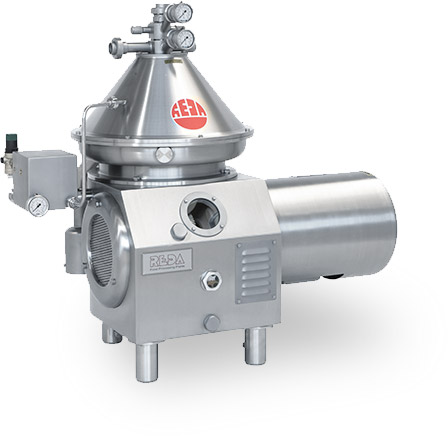

Milk Separators RE-T/TE

REDA self‐cleaning separators of RE-T/TE serie are specially designed to separate the fat content which is naturally present into the raw milk before its processing. This range of centrifuges can perform more processing like the milk total skimming, the milk partial skimming (fat standardization) or just make a milk cleaning.

The very high rotation speed of the bowl, combined with the special design of the discs stack, asssures high grade separation efficiency of solids/heavy parts with very small diameters (fat, dirty, spore and bacteria, etc.). Milk inlet comes under pressure thanks to a soft inflow system that accelerates it to the separation speed without damaging the fat globules, very important characteristic also for the treatment of goat’s milk or sheep’s milk. The wide working surface, the high centrifugal force and the expulsion extremely fast of sludges, guarantee a great efficiency of separation and cleaning. After the passage inside the separator, no recovery pump is necessary because the skimmed milk and the cream exit under pressure.

The very high rotation speed of the bowl, combined with the special design of the discs stack, asssures high grade separation efficiency of solids/heavy parts with very small diameters (fat, dirty, spore and bacteria, etc.). Milk inlet comes under pressure thanks to a soft inflow system that accelerates it to the separation speed without damaging the fat globules, very important characteristic also for the treatment of goat’s milk or sheep’s milk. The wide working surface, the high centrifugal force and the expulsion extremely fast of sludges, guarantee a great efficiency of separation and cleaning. After the passage inside the separator, no recovery pump is necessary because the skimmed milk and the cream exit under pressure.

Main features

– Completely stainless steel execution

– High-grade finishing both for wetted and external parts to ensure proper sanitization and ease of cleaning

– Standardization device with high turbulence cream injection system

– Automatic solids ejections electronically controlled by PLC

– Possibility to execute manual discharges

– Self-cleaning device

– FREQ-CLUTCHTM: a specially designed variable frequency drive (VFD) system provides for fast and silent start, optimization of energy consumptions and quick speed recovery after solids ejections

– Direct gear transmission or by belt (FREE BELTTM), depending on the nominal flow rates

– Oil-bath lubrication without need of external lubrication circuit

– PRSTM system: new design of solids holding space with larger volume than the past.

By this means, significantly longer production intervals were able to be achieved between the ejections, resulting in a lower number of discharges, a reduction of the discharged volume and so lower product losses during each discharge

– SOFT-SPINDLETM: vertical rotating shaft with flexible gear system that guarantees almost unlimited duration to bearings and gears

– SERVICE-FREETM: design and number of gaskets subject to wear minimized to have easy and inexpensive maintenance

– Setup for automatic washing at the end of production in a closed cycle (CIP washing)

– Electrical panel with PLC and control through HMI with colour touch screen

In option:

– automatic back pressure valve on the processed product (standard on bigger size models)

– machine mounted on skid with preconnections (only for small-medium size models)

– REDA RTM automatic standardization system

– High-grade finishing both for wetted and external parts to ensure proper sanitization and ease of cleaning

– Standardization device with high turbulence cream injection system

– Automatic solids ejections electronically controlled by PLC

– Possibility to execute manual discharges

– Self-cleaning device

– FREQ-CLUTCHTM: a specially designed variable frequency drive (VFD) system provides for fast and silent start, optimization of energy consumptions and quick speed recovery after solids ejections

– Direct gear transmission or by belt (FREE BELTTM), depending on the nominal flow rates

– Oil-bath lubrication without need of external lubrication circuit

– PRSTM system: new design of solids holding space with larger volume than the past.

By this means, significantly longer production intervals were able to be achieved between the ejections, resulting in a lower number of discharges, a reduction of the discharged volume and so lower product losses during each discharge

– SOFT-SPINDLETM: vertical rotating shaft with flexible gear system that guarantees almost unlimited duration to bearings and gears

– SERVICE-FREETM: design and number of gaskets subject to wear minimized to have easy and inexpensive maintenance

– Setup for automatic washing at the end of production in a closed cycle (CIP washing)

– Electrical panel with PLC and control through HMI with colour touch screen

In option:

– automatic back pressure valve on the processed product (standard on bigger size models)

– machine mounted on skid with preconnections (only for small-medium size models)

– REDA RTM automatic standardization system