Normally milk is standardized through adjusting the fat content in the milk and cream by mixing in the storage tanks. Unpredictable fluctuations in the raw milk fat content, along with the need for faster and precise standardization has bring to the development of automated system.

The automatic standardizer, compared to traditional mixing in tanks, assures higher precision, constant product quality and time saving.

How does it work?

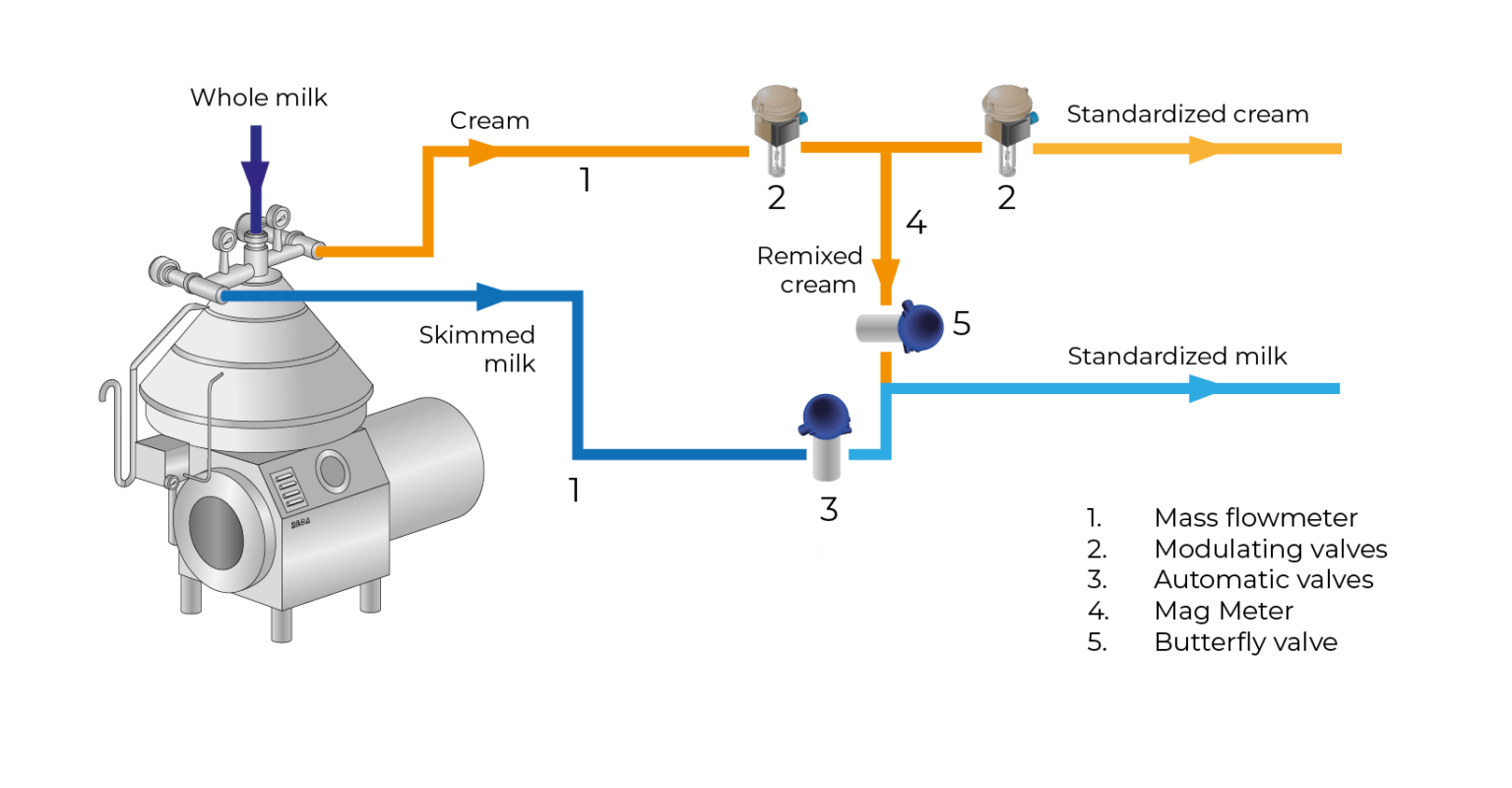

A milk or cream standardizer, connected to a skimming separator, controls the fat content by operating on the valves set at the separator’s outlets. For standardization, raw milk or pasteurized milk are separated into skimmed milk and cream by a milk separator. Part of the high fat cream is added back into the skimmed milk in exact proportions in order to produce standardized milk with precisely the right fat content.

3 steps to easy production

Higher precision for uncompromised quality

The system has two density meters for milk and cream in order to get a high accuracy both in the milk and cream fat content. The accuracy can be considerably improved by the “automatic calibration system” standard and included (that can be selected from the operator) in order to consider the real operating conditions. The automatic setting system intervenes on the equations of the standardization to immediately adjust the deviation between real data and theoretical data.

Easy operation to enjoy the production

REDA Automatic in-line standardizing unit operates following a different logic than traditional standardizers in tanks and are specifically designed to get both milk and cream in‐line standardization at the same time, without needing to know the inlet fat content.

Three steps to an easy production:

- insert a production cycle in the operator panel

- set milk and cream fat content

- system recognizes real butterfat content and adjust valves

Time saving and minimized product loss

The operator just needs to set the required output parameters, which grants lots of time savings. Program and product changes are readily adjusted by the standardizer control system.

The excess of fat is extracted already standardised. The resulting cream has a higher added value and and does not have to be standardised again with the risk of product loss. A step that would be necessary if the cream was not already standardised.

Main Advantages

- Accuracy and precision

- Automatic regulation to save time

-

Constant result

-

In-line process to increase production

-

Uniform product quality

- Accurate control for the best ROI in the market