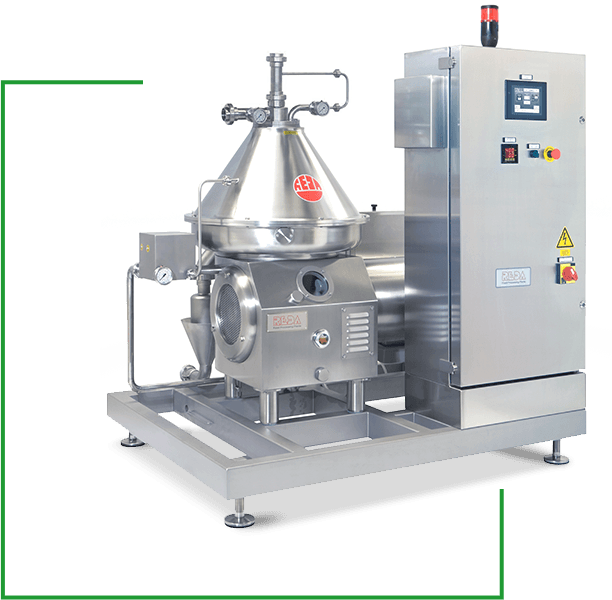

bacteria separators RE-B

Why is the removal of bacteria in milk so important?

Main features

– 100% stainless steel execution

– High-grade finishing both for wetted and external parts to ensure proper sanitization and ease of cleaning

– Automatic solids ejections electronically controlled by PLC

– Possibility to execute manual discharges

– Self-cleaning device

– FREQ-CLUTCHTM: a specially designed variable frequency drive (VFD) system provides for fast and silent start, optimization of energy consumptions and quick speed recovery after solids ejections

– Direct gear transmission or by belt (FREE BELTTM), depending on the nominal flow rates

– Oil-bath lubrication without need of external lubrication circuit

– PRSTM system to reduce the losses of milk during discharges. Thanks to the new design of the sludge chamber, featuring a larger volume to increase the sludge accumulation during the treatment phases. This means longer discharging times, with a lower number of discharges and, consequently, less losses of milk.

– SOFT-SPINDLETM: vertical rotating shaft with flexible gear system that guarantees almost unlimited duration to bearings and gears

– SERVICE-FREETM: design and number of gaskets subject to wear minimized to have easy and inexpensive maintenance

– Setup for automatic washing at the end of production in a closed cycle (CIP washing)

– Electrical panel with PLC and control through HMI with colour touch screen

In option:

– automatic back pressure valve on the processed product (standard on bigger size models)

– skid with preconnections (only for small-medium size models)100