Automatic standardizers RTM

Menu

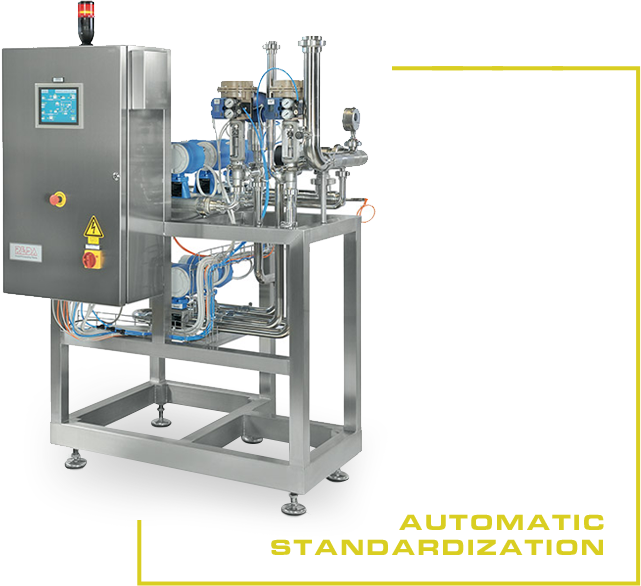

Automatic Standarizer RTM

Top solution for automatic milk and cream standardization

Normally milk is standardized through adjusting the fat content in the milk and cream by mixings directly in the storage tanks. This means losses of time and additional costs for the necessary handlings and controls. Moreover it results very difficult to obtain the exact concentration of the cream and to avoid remaining at the end of the standardization process.

REDA automatic standardizers of RTM series are specifically designed to get both milk and cream in‐line standardization at the same time.

This process is made without needing to know the fat content of the milk at the inlet. These units are conceived to work together with a skimming separator and in-line with a pasteurization plant.

Working system

Speed regulation is an exclusive feature of the RTM standardising unit: in facts the system pre‐sets a regulation of the flows (according to the required standardization rate) during the system starting and sterilization phase and performs the fine regulation when the milk arrives. Density measurers, placed on milk and cream line, assure a very high precision level and accuracy in standardization thanks to the automatic regulation system that keeps in mind the real operative conditions. In every moment the system recognizes the fat level into the incoming milk and calculates the flows of milk and cream, acting by consequence on automatic regulation valves.

The automatic calibration system operates on the standardising calculation curves to adjust any deviation from the theoretical data, permitting the regulation of the standardising system without the intervention of skilled technical personnel.

Advantages of the automatic standardization vs. manual methods

REDA automatic RTM units give several advantages compared to manual standardization methods:

– Accuracy and precision

– Non-influence of season variations in fat content

– Fast regulation speed

– Uniform product quality

– Quality in the final product without comparisons

– No need of skilled technical personnel

– Energy and time saving

– Increase of the volumes to be processed

– Diversification of the range of products